NE SARE 2009 Research Project FNE09-662

Final Report

-

Project name and contact information

Better Wine Grape Quality using Combined Vine Training And Canopy

Management

FNE09-662

Richard Lamoy

456 Soper Street

Morrisonville,

NY 12962

Phone – 518-643-0006

e-mail – richL@charter.net

-

Goals

The goal of the project was to see if it is

possible to improve the quality of wine grapes by using a

combination of training systems and canopy management to match the

varieties. The objective was to use three existing varieties of wine

grapes – Frontenac, Chardonel and Leon Millot and train them to both

Vertical Shoot Positioning and 4 Arm Kniffen. Within those systems

they were to be compared using Shoot Thinning, Cluster Thinning and

use a control or check. Data results will compare yield and quality

as measured by visual inspection of the fruit and sugar and acid

measurements close to and at harvest.

-

Farm profile

The farm name is Hid-In-Pines Farm located at

456 Soper Street

in Morrisonville, NY. In the past it operated as a fresh

vegetable and fruit farm as well as a small dairy. The farm is

currently transitioning to a vineyard and soon a winery. The farm is

an offshoot of Lamoy’s Produce and they are both part of the same

physical farm of approximately 90 acres. The vineyard consists of

three acres of cold hardy wine grapes. I am in the process of

converting existing outbuildings into the new farm winery and am in

the process of licensing as a Farm Winery and expect to open the

winery in the next year.

-

Participants

The technical advisor on this project was Kevin

Iungerman who is the Cornell Cooperative Extension Northeast NY

Commercial Fruit Program Specialist.

Others, while not direct paid consultants, who

visited and provided some collaborative feedback in their

specialties, were:

Justine Vanden Heuvel – Cornell University – Assistant Professor

Viticulture

Wayne Wilcox – Cornell University

– Professor Plant Pathology - Viticulture

Tim Martinson – Cornell University

- Senior Viticulture Extension Associate

Anna Katharine Mansfield – Cornell University - Assistant Professor of Enology

Chris

Gerling-

Cornell

University-

Enology Extension Associate

-

Project activities

The project began by examining the vines in the

early spring after an unusually cold winter event. The temperatures

were substantially colder than in the past fifteen years.Normal lows

have ben in the -10 to -12F range and this year we reached -22F two

times. The results of the

inspection indicated that the variety Frontenac was fine with very

good bud survival. The Leon Millot was generally in good shape with

an acceptable bud survival. The Chardonel suffered terribly with

dieback to the snowline at the time of the cold event to about 15

inches above ground. That eliminated Chardonel from being useful in

the trial. After consultation with the grant supervisor, a decision

was made to switch that variety to LaCrosse which had good bud

survival and was in an acceptable layout for the trial. Because of

its trailing tendencies it was decided to be trialed using Top Wire

Cordon and 4 Arm Kniffen. Each system has a panel of each treatment

(4 vines). By way of example Frontenac trained to VSP has 4 vines

between posts (a panel rep) each for the Shoot Thinned, Cluster

Thinned and the control or Check.

Work began in the vineyard doing preliminary

dormant season vine pruning keeping in mind the training systems.

The number of retained nodes (buds) was based on making bud cuts to

determine bud mortality rates. The desired retained nodes were set

at a base of 5 nodes per foot of canopy for Frontenac, 6 nodes per

foot for Leon Millot and 6 nodes per foot for LaCrosse.

The retained nodes were counted and recorded after pruning.

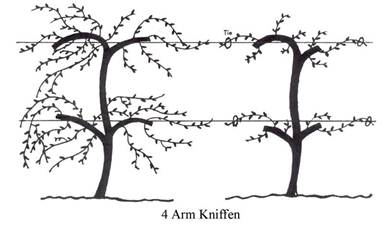

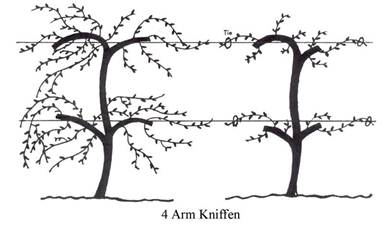

Keep in mind that the foot canopy includes two levels with the 4 arm

Kniffen and the number of nodes was divided between these two

levels. For example, the Frontenac used 3 nodes per foot on the top

wire and two nodes per foot on the bottom fruiting wire.

Shortly

after spring pruning, the training systems were established. The

Frontenac and Leon Millot had all previously been trained to

Vertical Shoot Positioning (VSP). At pruning, two long canes near

the trunk at the fruiting wire were retained. These were trained up

to the top wire and tied down to it and thus the four arms were

established. Some canes were a bit short to allow for a fully spread

canopy on the top wire, so extra nodes were retained on the lower

wire in those cases. The LaCrosse had been previously trained for 4

Arm Kniffen. It was decided to cut off the lower cordon arms to

convert to Top Wire Cordon (TWC) instead of VSP. The top wire

cordons were more completely formed in general leading to that

decision.

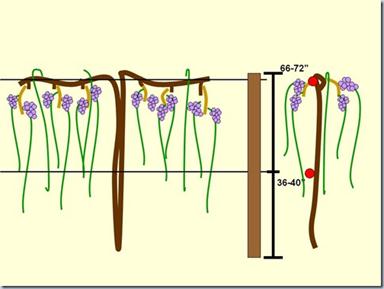

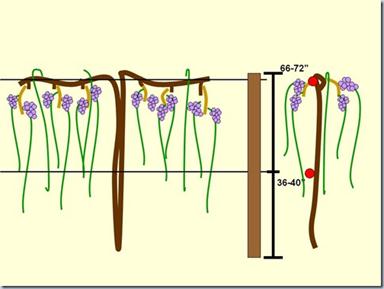

To better

understand the types of training systems used see Diagram 1

on the next pages.

Diagram 1

Vertical Shoot Positioning

Vertical Shoot Positioned (VSP)

Top Wire Cordon (TWC)

Early season LaCrosse Vine on

Top Wire Cordon

In

Season Pruning and Training

As the growing season progressed the vines were

trained and maintained to the appropriate systems. Times needed for

these operations were recorded and later tabulated for each

treatment panel. These were listed as Pass One, Pass Two, etc.

The VSP shoots were trained between the catch

wires. As the shoots grew over the top wire by a few feet, they were

hedged off to just above the top wire.

The vines trained to the 4 Arm Kniffen were

allowed to grow the shoots as long as they got. They were trained to

droop down while straightening them out (combed).

Any shoots that interfered with the tires of the tractor

running over them for normal vineyard operations were cut off at the

ground (skirted) to prevent the shoots from being broken off.

The Top Wire Cordon (TWC) vines were kept tied

to the top wire and the new shoots were trained downward and combed

to open the canopy up. If the vines touched the ground as above,

they were skirted back.

Note:

Not all of the top wire cordons were well

formed with the LaCrosse and adjustments were made to them to try to

increase node count to the desired number. This surely influenced

the results and because of this should be replicated again to

improve the reliability of results.

At the appropriate time shoot thinning and

cluster thinning were implemented aiming for the desired number of

shoots and clusters per foot and recorded. Shoot thinning was aimed

at a final shoot count of 5 shoots per row foot (combined wires) for

both all treatments. All treatments, including the Check were

appropriately hedged or skirted and leaf pulling took place to

expose the fruit.

Pictures were taken as the year progressed to

help document the results of these operations.

Sampling and Testing

Samples were taken of the fruit beginning in

mid September to monitor ripening and potential differences in the

fruit quality. Three samples were taken for each treatment

approximately ten days apart. A final sample was taken at harvest to

gather the final fruit quality sample. Fifty grapes were taken

randomly from each panel of each variety. Each sampling period took

readings of eighteen (18) individual samples.

Each sample of the first

test tested the sugar (brix) and acid (pH) and was recorded. The

following samples, as well as the final sample, tested for brix, pH

and TA (titratable or total acidity). All the samples were recorded

in a spreadsheet as part of the final results and is available.

Notes were also taken of fruit quality and canopy density as they

became apparent.

The sample berries were crushed and the juice

extracted for testing. The brix was measured using a handheld

refractometer. The pH was measured using a portable electronic pH

meter after calibrating. The TA was measured using a Hanna

Instruments 84102 Mini Titrator with digital readout after

calibration.

Harvest

Each variety of grapes was all harvested the

same day so the results would be consistent.

Frontenac was harvested first on October 15, 2009. LaCrosse

was harvested October 17, 2009 and the Leon Millot was harvested on

October 21, 2009.

Every vine of every treatment was picked into

its own grape lug. They were individually weighed in pounds to the

tenth pound and recorded. As the vines were picked, the harvested

clusters were counted and recorded. These two measurements allowed

for average vine and cluster weights for each treatment. It also

makes it possible to give acre equivalent yields based on vine and

row spacing.

-

Results

There was a lot of information gathered from

this trial. In general I can say that based on a single year’s data

collection, it certainly is possible to influence and increase the

quality of wine grapes.

I will list the information here in a condensed format for the

results of the trial. After that I will try to interpret some of

these results and what it can mean. Like any other study, the

validity of the data would be enhanced with further testing in

future years. Because of this I will be seeking an extension to the

grant for further testing.

Frontenac

The VSP required more time for training and

summer pruning than the 4 Arm Kniffen. It took three large hedgings

to get the VSP down to a manageable size to not shade the fruit. The

4 Arm Kniffen stayed visibly more open with the fruit more exposed

for ripening, reducing the need for pruning and leaf pulling.

To sum up the results of the Frontenac grapes,

the highest quality grapes were obtained using 4 Arm Kniffen and

Shoot Thinning. Final test results were a brix of 21.6, pH of 3.19

and a TA of 14 g/L. This was the best combination and at a yield of

28.3 pounds per vine average would give a yield of about 9.78 tons.

This results in a great increase in the yields over of any of the

VSP treatments and a 67% yield increase over VSP Shoot Thinned. In

this case we obtained two thirds more yield of a higher quality

product.

For comparison I assign a value of $1000 per

ton for grapes of minimum brix level of 21, $900 for brix between

19.5 and 21, $800 over 18 but under 19.5 and $500 for a brix of

under 18. Actual price differences will vary from area to area and

variety to variety, but this shows how price drops for lower sugar

and higher acids.

Following

is a summary of comparative treatments:

Frontenac

AvgYield

lbs Tons/Acre

brix

pH

TA

Price

Value/Acre

VSP Shoot Thinned

17.0

5.87

19.2

3.04

16.7

$800

$4696

4 AK Shoot Thinned

28.3

9.78

21.6

3.19

14.0

$1000

$9780

VSP Cluster Thinned

18.4

6.34

18.7

3.02

16.1

$800

$5072

4 AK Cluster Thinned

29.1

10.05 20.0

3.14

15.2

$900

$9045

VSP Check

24.4

8.41

15.0

2.95

17.4

$500

$4205

4 AK Check

29.2

10.07 18.8

3.04

15.3

$800

$8056

The differences in this case between Shoot

Thinned and Cluster Thinned are small and but demonstrates a big

difference between VSP and 4 Arm Kniffen.

Leon

Millot

The Leon Millot grapes were in two adjacent

rows, with one having VSP training and the other the 4 Arm Kniffen.

The training was implemented the same as the Frontenac, training the

extra two arms from long center canes retained at dormant pruning. A

higher than normal node count was retained at dormant pruning to

allow for a forty percent dead primary bud count. Differences

between the two systems was not as pronounced as with the Frontenac,

but still existed. The 4 Arm Kniffen required less summer pruning

and training time than did the VSP. The canopy was also visibly less

dense than the VSP and in a normal year would have enabled at least

one less spraying.

For comparison I assign a value of $1000 per

ton for grapes of minimum brix level of 20, $800 over 18 but under

20 and $500 for a brix of under 18. Actual price differences will

vary from area to area and variety to variety, but this shows how

price drops for lower sugar and higher acids.

Following

is a summary of comparative treatments:

Yield lbs Tons/Acre

brix

pH

TA

Price

Value/Acre

VSP Shoot Thinned

8.3

2.85

19.0

3.14

9.1

$800

$2280

4 AK Shoot Thinned

9.0

3.11

20.0

3.18

8.3

$1000

$3110

VSP Cluster Thinned

6.1

2.11

19.0

3.13

9.3

$800

$1688

4 AK Cluster Thinned

7.5

2.57

20.0

3.26

7.0

$1000

$2570

VSP Control

5.4

1.87

19.2

3.12

9.2

$800

$1496

4 AK Control

8.6

2.97

18.6

3.21

7.4

$800

$2376

Although the yield differences aren’t as

striking with the Leon Millot, they are still significant. The

quality in general was also better resulting in almost a forty

percent increase in value per acre for the 4 Arm Kniffen grapes over

the VSP. Shoot thinning with this variety in this case resulted in

definite yield and quality increases over cluster thinning.

Leon Millot Grapes Before

Picking- VSP Shoot Thinned

LaCrosse

The LaCrosse vines were trained to Top Wire

Cordon (TWC) and 4 Arm Kniffen. The TWC vines were not all well

formed so some of the yields and results may have been skewed. A

follow-up year of testing should be done with better developed vines

for more reliable results. Also the east side of the 4 Arm Kniffen

LaCrosse were shaded for an hour or so in the morning which resulted

in visibly more dew staying on the vines later in the day. A further

year’s testing could include reducing the shading by removing a few

trees.

For LaCrosse- a white grape -I assign a value

of $1000 per ton for grapes of minimum brix level of 18, $800 over

15 but under 18 and $500 for a brix of under 15

. Actual price differences will vary from area to area and

variety to variety, but this shows how price drops for lower sugar

and higher acids.

Following

is a summary of comparative treatments:

Yield lbs Tons/Acre

brix

pH

TA

Price

Value/Acre

TWC Shoot Thinned

8.0

2.75

17.0

3.13

9.8

$800

$2200

4 AK Shoot Thinned*

15.2

5.25 15.4.6

3.08

11.1

$800

$4200

TWC Cluster Thinned

14.7

5.08 17.0

3.11

9.5

$800

$4064

4 AK Cluster Thinned

17.41

5.99

15.6

3.20

7.8

$800

$4792

TWC Control

8.4

2.88 18.0

3.11

9.7

$1000

$2880

4 AK Control

19.8

6.84

15.6

3.21

9.5

$800

$5472

*This panel of vines was shaded in September

and October probably lowering potential sugars and possibly

increasing expected acid levels.

In the LaCrosse because not all the vines were

well formed and there was some shading, the results are less

meaningful, but in general they demonstrated a yield increase with

four cordons than two. Quality was alright, but brix levels were low

due to the cool growing conditions. Acid levels were good in spite

of this demonstrating that they were ripe, just low in sugar. That

difference is easier to adjust for than high acid, so the value is

good.

LABOR

The following table summarizes the time

involved in the labor of training and tying the vines of each

treatment during the growing season. It logs the actual times needed

for each treatment. By gathering this information it takes any extra

labor needed for any treatment into consideration. By way of

example, the Frontenac VSP panel took an hour and 15 minutes per 4

vines to keep the canopy managed for this type of treatment. The

Frontenac 4 Arm Kniffen took a total of 32 minutes or 43 minutes

less per 4 vines. At a density of 691 vines per acre, the time

savings would be 123 hours of labor per acre. This is a considerable

time saving for one treatment over another.

|

|

|

Labor

|

2009

|

|

|

|

|

|

|

|

|

Total Time

|

|

Labor Date

|

|

|

|

|

Hours:

Minutes

|

|

|

Variety

|

Training

|

Canopy

|

Panel

|

|

|

|

|

System

|

Management

|

Number

|

|

|

|

Frontenac

|

VSP **

|

Shoot

Thinned

|

One

|

1:15

|

|

|

Frontenac

|

VSP **

|

Cluster

Thinned

|

Two

|

1:35

|

|

|

Frontenac

|

VSP **

|

Control

|

Three

|

1:29

|

|

|

Frontenac

|

4 AK ***

|

Shoot

Thinned

|

One

|

0:35

|

|

|

Frontenac

|

4 AK ***

|

Cluster

Thinned

|

Two

|

0:52

|

|

|

Frontenac

|

4 AK ***

|

Control

|

Three

|

0:55

|

|

|

Leon Millot

|

VSP

|

Shoot

Thinned

|

One

|

1:42

|

|

|

Leon Millot

|

VSP

|

Cluster

Thinned

|

Two

|

2:00

|

|

|

Leon Millot

|

VSP

|

Control

|

Three

|

1:49

|

|

|

Leon Millot

|

4 AK ***

|

Shoot

Thinned

|

One

|

1:13

|

|

|

Leon Millot

|

4 AK ***

|

Cluster

Thinned

|

Two

|

1:32

|

|

|

Leon Millot

|

4 AK ***

|

Control

|

Three

|

1:34

|

|

|

LaCrosse

|

TWC *

|

Shoot

Thinned

|

One

|

0:29

|

|

|

LaCrosse

|

TWC *

|

Cluster

Thinned

|

Two

|

0:30

|

|

|

LaCrosse

|

TWC *

|

Control

|

Three

|

0:26

|

|

|

LaCrosse

|

4 AK ***

|

Shoot

Thinned

|

One

|

1:15

|

|

|

LaCrosse

|

4 AK ***

|

Cluster

Thinned

|

Two

|

1:15

|

|

|

LaCrosse

|

4 AK ***

|

Control

|

Three

|

0:50

|

-

Conditions

There are certain conditions that were

encountered this year that may have caused some deviation in

expected results. First of these was the unusual cold spell we had

in January of this year. That affected the condition of the vines,

with somewhat reduced bud survival. As a result some of the vines

may have had less bearing shoots on them than expected- notably the

LaCrosse and Leon Millot. Like was previously mentioned, Chardonel

was supposed to be the third variety, but was switched with the

LaCrosse because it was so badly damaged from the cold.

Also a factor this year was the cold, cloudy

weather this spring, summer and fall. We ran about 200 degree days

short of normal, logging about 2200 growing degree days instead of

2400 which is more typical. July and August were very wet months

which dictated an extra spraying for disease over what might have

been needed.

The trial vineyard encountered some shading

from the native trees on the east side of the LaCrosse. I believe

this led to lower brix and higher acid conditions than would be

expected without the shading. This only affected the vines adversely

in September and October, but this year those were cloudy and cool

months compounding the problem of ripening. I will be seeking to

remove or trim the trees which were causing the shading.

-

Economics

In general it is certainly possible to increase

the value of the wine grapes both through increased yields and

improved quality. Furthermore net farm income could be increased by

getting higher returns for the crop along with diminished labor

requirement. Some of the treatments required substantially less

labor input during the growing season as well as harvest labor.

Using Frontenac by example see the following:

Frontenac

Labor

Net

Tons/Acre

Price/T

Value/A

Hours/$10x172*

VSP Shoot Thinned

5.87

$800 $4696

$2150

$2546

4 AK Shoot Thinned

9.78

$1000 $9780

$1003

$8777

VSP Cluster Thinned

6.34

$800 $5072

$2723

$2349

4 AK Cluster Thinned

10.05

$900

$9045

$1490

$7555

VSP Control

8.41

$500

$4205

$2551

$1653

4 AK Control

10.07

$800 $8056

$1576

$6479

*Spacing provides approximately 688 vines / Acre divided by 4 = 172

We can see in this example that even though the

cluster thinned treatment of 4 Arm Kniffen and even the Control gave

a greater yield, the greatest return was obtained by the Cluster

thinned 4AK because of reduced labor needs. Should these grapes be

made into wine instead of selling as grapes, there is the potential

for even greater returns.

-

Assessment

This trial project shows that there is great

potential to maximize yield, increase quality and net farm profit.

Further testing should be done to validate these findings. More

years of data and expanded replications would be of value. I see

this project as validating the concept and the additional testing

would give reliability to the findings. In the future it would

probably be worth expanding the number of training systems, and

varieties this work was done with. It may be possible to reliably

predict the best combination of variety, training system and canopy

management type. Armed with that information, it would increase the

net farm income and sustainability of adopting farmers.

-

Adoption

At this point, I would advise

caution in adoption of the results of this project trial. It

certainly would value anyone considering adopting this to give it a

try on their individual farm, possibly in a side by side comparison.

The results may vary from farm to farm based on soil types, climate

and inputs. After further testing on my vineyard, I will probably

adopt these concepts to maximize farm income.

11.

Outreach

I see the outreach part of this project as a

continuing process and hope to continue the dissemination of the

results for the next year or more. This current year the outreach

consisted of several methods of dissemination.

Onsite

Field Meetings.

A tour

and field meeting was held at the vineyard on July 17 and was

attended by a number of local vineyard owners. Joining the group was

Justine Vanden Heuvel and Wayne Wilcox both from Cornell. Justine

reviewed the trial and made a few suggestions for canopy management.

Mr. Wilcox checked the vineyard for disease since he is the Plant

Pathologist expert at Cornell. He noted the lack of any disease

pressure in spite of the rainy season. The following day the group

and an expanded crowd attended a field session at the Willsboro Cold

Hardy Grape Trial after visiting the UVM NE1020 Grape Trial in

Burlington Vt. Justine gave a talk about Canopy Management such as I

have implemented in this project.

Wayne Wilcox discussed the value of canopy management in the

control of plant disease pressure to minimize the number and amount

of needed sprays. I showed the vineyard sprayer developed for the

Willsboro trial based on my own I made and alluded to the value of

such a sprayer in being able to control pests with a minimal spray

program.

The next

meeting was held here on August 15, 2009 and had approximately 15

attendees on hand. Notices were sent out through e-mail, the local

press after contacting the local Extension office and online as

posted through the UVM Cold Climate site at

http://pss.uvm.edu/grape/

.An overall summary of the project was given out in a binder along

with a site map showing the layout of the newly planted trial

expansion and a PowerPoint slide show. The meeting covered the trial

and its layout. We conducted a walking tour and included a

discussion of what was being done, studied and compared. I went over

data collection and basic training and canopy management.

A follow-up field meeting was held on September

10 and included a group from the Lake Champlain Grape Grower’s

Association. We did a walking tour of the vineyard and I showed the

vines involved in the trial. At that point the differences in

Training Systems and Canopy Management were becoming very apparent.

A number of attendees expressed an interest in adopting the training

system used after seeing preliminary results. I cautioned that the

results are very preliminary and not replicated yet so if they adopt

the system, they should do so with guarded caution. We covered the

test equipment being used to gather the sample data which I shared

with the group at a later meeting.

There were eight volunteers that showed up to

help with harvest in the larger vineyard. A number of them were

growers with their own vineyards, so I showed them the different

Training Systems and Canopy Management treatments of this trial.

Many expressed an interest in the systems and asked to be sent the

final data.

Networking with Extension

Cooperative Extension personnel were used

wherever I could to help with the dissemination of data. Amy Ivy of

Clinton County Extension helped write press releases. As stated

above joint meetings and involvement of Extension or Cornell

personnel were used whenever possible. Also visiting the vineyard

was Tim Martinson, Cornell Head Extension Associate of Viticulture.

He invited me to a meeting held November 12 in Burlington Vt

as part of a grant for studying ways Extension may help promote Cold

Hardy Grapes. I made a presentation to the group of the results I

obtained from this grant study. Head extension personnel from a

number of states were there as well as industry leaders and

representatives. Also

visiting and discussing ways to improve grape quality for cold hardy

grapes were Anna Katharine Mansfield and Chris Gerling. Chris is

from Extension Viticulture and Anna Katharine is form the Enology

Dept of Cornell.

Printed

Material

As stated above, a pamphlet binder was handed

out at a meeting which included initial planning, trellising and

training in the trial along with a PowerPoint Presentation. A copy

of this was also brought to the Clinton County Cooperative Extension

office and added to their file of material available to interested

parties. It is also available to other offices upon request.

A summary of this study is being prepared and

will be available to all interested as either printed material or in

an Excel Spreadsheet format. The summary data is also being sent to

interested parties involved in the Burlington Vt Cold Climate Grape

Conference since a number of attendees requested the information.

News

Media

With a press release from Kara Dunn, publicist

for NY Farm Viability and others, a number of articles appeared in

print and online. They were aimed at getting general information out

to the public and improving exposure and public interest in cold

hardy grapes. Some of the articles were in

Plattsburgh

Press-Republican

http://www.pressrepublican.com/sunday/local_story_284001033.html

,

Adirondack

Harvest Newsletter

http://www.adirondackharvest.com/files/Summer-2009-low-res.pdf

Denton

Publications

http://www.denpubs.com/Articles-c-2009-10-15-63579.113116-sub8589.113116_North_Country_becoming_wine_country_for_local_grape_growers.html#nogo

AdirondackAlmanack.com

http://www.adirondackalmanack.com/2009/10/north-country-grown-wines-win-awards.html

Strictly Business Monthly

http://www.sbmonthly.com/magazine/2009/10/Growing%20Wine%20Grapes%20in%20the%20North%20Country.php

and Northern NY Agricultural Development site

http://www.nnyagdev.org/press-releases/2009/press-09-30-09-b.htm.

AThrough this publicity I hope to develop a

greater understanding from the public in this valuable crop and the

future of it in our economy. This interest will help promote good

will and increased sales to all wineries and vineyards and help

foster an increased sustainability.

-

Report Summary

The purpose of this project was to determine if

it is possible to obtain better wine grape quality using a

combination of vine training systems and canopy management. Several

vine varieties were used in the project and were trained to two

training systems each. They were further divided into two canopy

management systems of Shoot thinning and Cluster thinning and also

included a check or control in the project. Data was collected to

give comparisons of each combination for each variety. The data

included yield and comparative quality measurements through sugar

and acid levels. By comparing these numbers obtained in the data

collection, it is reasonably certain that an improvement in quality

is possible through these reproducible systems. Furthermore it is

possible to also increase the yields as well as quality.

Richard Lamoy, November 20.2009

Hid-In-Pines Vineyard

Hid-In-Pines Vineyard